Jim Lane

![Hydro-Man[1].jpeg](http://www.altenergystocks.com/wp-content/uploads/2017/08/Hydro_Man_1_.jpeg) HydroMan may do his hydrogen-shift thing via water, at will – but outside of the Marvel Cinematic Universe, we have some hydrogen issues.

HydroMan may do his hydrogen-shift thing via water, at will – but outside of the Marvel Cinematic Universe, we have some hydrogen issues.

Psst! Like cutting out a fossil hydrogen dependency for many biofuels.

But, new pathways ensure that the status hydroquo may not last for long.

A numbers of readers responding to “Biofuels from a raging fireball” (on research work with the raging fireball, Pyrococchus furiosus, to make biofuels and renewable chemicals from hydrogen gas and CO2) raised the question, where is all the hydrogen going to come from?

As many know, hydrogen is not found in a free state in nature in much quantity and we supply most of our hydrogen needs through steam reformation of natural gas, or cracking fossil petroleum. In other words, renewable fuels made using external hydrogen may well have a hidden fossil fuel dependency.

It all comes down to cost. There are alternative ways to make hydrogen gas, and renewable pathways for sure if society is not using them, it is generally due to cost issues. In there, to some extent because the costs associated with renewable hydrogen are generally internalized in the process, while many of the social costs of fossil fuels are externalized e.g. the venting of sequestered CO2.

The hydrogen dependency

Hydrogen gas is a dependency in a number of processes that make renewable fuels most notably, those that have a hydrotreating step to remove excess oxygen. That includes the upgrade of pyrolysis oils, and even the production of aviation biofuels from renewable oils (the HEFA pathway that is currently powering most of the current flight activity).

Those beyond H2.

Now, hydrogen gas is not a required production element. Fermentation of biomass to produce an alcohol fuel does not require it. The production of diesel and jet fuels fuels using the processes pioneered by Amyris (AMRS) and LS9 do not. Neither does Joule’s process, not Cool Planet’s drop-in fuels (we think). We’ll get to the interesting case of LanzaTech shortly. Upgrading alcohol fuels to hydrocarbons can be accomplished without hydrogen gas ORNL has developed such a process.

But some of the most promising companies are using hydrogen Coskata, Sundrop Fuels, Primus Green Energy being three examples of companies that have begun to source fossil natural gas to get affordable feedstock. But processes such as Honeywell’s (HON) UOP’s hydrotreating, used to make drop-in fuels with the Envergent process, or HEFA aviation biofuels in partnership with the likes of Dynamic Fuels and Solazyme (SZYM) well, they need hydrogen.

So, what about hydrogen gas can it be made renewably, and where and how?

The technical answer is, you bet. Affordably? Another question entirely. Let’s review the state of play with the two main pathways – and two outliers.

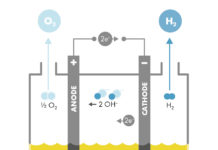

Electrolysis

The process? Hydrogen can be produced from water, and routinely is, using an electrolytic process that you can demonstrate in a high school lab.

The problem? The process will chew up some 35-50 kilowatt hours of electricity per kilo of hydrogen. There being roughly a kilo of hydrogen in a gallon of hydrocarbon fuel at $0.10 for lowest cost renewable electricity (e.g. wind), there’s $1.70-$2.50 cost per gallon just to provide the hydrogen feedstock, and you still have to pay for the process and whatever cost of aggregating CO2.

Solution? Advocates routinely talk about producing hydrogen using excess (and thereby, nominally priced) renewable power at times when the grid is loaded, rather than shunting biomass steam energy to cooling towers (as opposed to the turbines) or using large scale battery storage of the type that Duke Energy put in place at its Notrees wind farm in North Carolina.

Another solution. ORNL has developed a low-cost process – yet to be demonstrated at scale. More on that here.

Anaerobic digesters.

The process? Here, microbes chew waste materials and produce biogas, rich in methane.

The problem? Costs have been the issue. But systems have been getting bigger, and options for producing hydrogen from them are there, using essentially the same processes by which hydrogen is produced from natural gas.

Solution? As an example of progression in system size, Western Plains Energy announced plans to build a $40 million anaerobic digester to produce enough biogas to replace 90% of the fossil fuel used in the manufacturing process at the company’s 50-million-gallon Oakley ethanol plant. When completed, the digester is expected to provide 15 jobs converting manure, grain dust and food waste to power. The project received a $5 million grant in April from the U.S. Dept. of Agriculture, and $15.9 million one year ago when Kansas Gov. Sam Brownback redirected unspent American Recovery and Reinvestment Act funding to the project.

Steam reformation or other catalytic processes from biogas or biooil

The process? Cracking hydrogen from biomass using heat and catalysis.

The problem? Cost, again. Steam reformation itself has struggled with high costs associated with the high temperatures at which the system operates. But it has been a technology worth chasing, for in the development of F-T plants it eliminates both the need for expensive oxygen plants and larger footprints needed to deal with nitrogen dilution from air, lowering capex and space requirements.

Solution? In 2010, we reported on a team from East China University of Science and Technology and Guangxi University has conducted a study of hydrogen production via catalytic steam reforming of bio-oil in a fluidized-bed reactor. They note that “hydrogen production from renewable biomass is particularly adapted to sustainable development concerns. Biomass, a kind of renewable resource that adsorbs CO2 during its growth, contributes net zero carbon emissions when used to produce hydrogen.”

A system that has been attracting the most attention in this area is the ClearFuels gasifier, the star gasifier at Rentech’s (RTK) Product Demonstration Unit in Colorado. Unlike other gasifiers or pyrolysis processes, ClearFuels HEHTR is a one-step rapid steam reforming process that converts all the biomass to syngas with no char, no liquid intermediates, no ash slagging/fouling and low tar content.

The technology has operational controls for a tunable hydrogen to syngas ratio of 1:1 up to 3.5 to 1, while also interchangeably running on syngas, tailgas, biogas or natural gas.

A first outlier. Syngas as a source of hydrogen and renewable fuels, all at once.

You may recall that LanzaTech can use hydrogen-free gases for the production of ethanol. That is because their propr

ietary microbe can produce hydrogen from carbon and water as required.

Which, of course, raises the possibility of combining a LanzaTech-type process with a process that needs hydrogen and obtaining both feedstocks at the same time from synthesis gas (a combination of hydrogen and carbon monoxide), produced by gasifying biomass. Just a matter of membrane separation of the hydrogen gas. Voila, renewable hydrogen, ready to be fed to a second system that uses CO2 and hydrogen to make fuels.

A second outlier – mimicking photosynthesis.

As you might have reflected during your reading this morning, what can plants teach us? Clearly they are obtaining hydrogen to make their own biomass, from water presumably affordably, since trees are not filing for bankruptcies.

In California last week, HyperSolar announced its plan to build renewable hydrogen generators for commercial use. Named the H2Generator, the company’s first commercial product is expected to sell at a substantially lower price than other renewable hydrogen systems that rely on expensive and energy intensive electrolyzers to split water.

By optimizing the science of water electrolysis, the low cost device mimics photosynthesis to efficiently use sunlight to separate hydrogen from water, to produce environmentally friendly renewable hydrogen.

Tim Young, CEO of HyperSolar commented, “We believe that our intensive R&D efforts will finally pay off in the form of a go to market commercial product. One key discovery was an efficient and low cost polymer protective coating that will allow us to protect solar devices against photocorrosion. Using this coating to treat traditional silicon solar cells, we are able to eliminate the expensive electrolyzer by integrating the electrolysis function directly into a solar cell immersed in water.

“We have given our tech team the green light to complete the product design required to build the first demonstration system,” Young continued. “With a demonstration system in hand, we can then move to the manufacturing phase of the business.”

The HyperSolar H2Generator will be designed to be a linearly scalable and self-contained renewable hydrogen production system. As a result, it is intended to be installed almost anywhere to produce hydrogen fuel for local use. This distributed model of hydrogen production will address one of the greatest challenges of using clean hydrogen fuel on a large scale – the need to transport hydrogen in large quantities.

The bottom line.

Digesterati, take faith. There are multiple paths to renewable hydrogen all a matter of cost. Our take: look for symbiotic systems, of the LanzaTech type we discussed above, where hydrogen or electricity becomes available as a residue from another process. In terms of bolting on to a second technology, there’s no better way to be capital light, and get closer, faster, to parity costs with fossil pathways to hydrogen.

Disclosure: None.

Jim Lane is editor and publisher of Biofuels Digest and BioInvest Digest where this article was originally published. Biofuels Digest is the most widely read Biofuels daily read by 14,000+ organizations. Subscribe here.