David Appleyard

A dramatic turnaround in the wind technology supply chain could bring opportunities for qualified suppliers, finds research by BTM Consultant ApS.

Over the past five years the whole of the wind technology supply chain has been in flux. The industry has seen a dramatic turnaround, with a negative supply situation for some key components and materials transformed into the current position, with a significant supply surplus. We present the key findings of the latest BTM Consult Supply Chain Assessment report.

Slower than expected economic recovery in the U.S., combined with the eurozone sovereign debt crisis and most recently the Chinese government’s effort to ‘overhaul’ the local wind industry, have completely transformed the wind industry supply chain. So concludes the latest in the biennial supply chain report from BTM Consult ApS, now a part of Chicago-based consultancy firm Navigant, Inc.

This comprehensive analysis reveals that over the past five years the industry has seen a dramatic turnaround, with a negative supply situation (2005-2008) for some key components and materials transformed into the current position with a significant surplus. Furthermore, with overcapacity now the case for most key components and materials, turbine prices have dropped to a level where both original equipment manufacturers (OEMs) and sub-suppliers are failing to see profitability, suggesting a tough time for the industry and a likely restructuring.

Indeed, in response to a slump in demand and fierce competition based on both quality and price, some suppliers have already reduced or suspended production with even some Chinese companies shuttering their businesses. But BTM believes it is not necessarily a bad thing for wind to be forced to provide products with low cost and high quality. They argue that clear underlying trends of ‘a flight to quality’ and consolidation have actually brought more opportunities to qualified suppliers with strength in both technology and finance. This is becoming vital, in particular to cater for the offshore wind market, where turbine OEMs already face a sourcing challenge for large components and equipment (for turbine manufacture and installation) and an even greater challenge in achieving rapid industrialization.

A Supply Chain in Flux

According to BTM, there have been significant changes in the supply chain for the wind power manufacturing industry over the past five years, most recently triggered by the worldwide economic downturn. The tight supply chain situation has been eased since the severe global financial crisis weakened the growth rate of wind power deployment two years ago. A balance of supply and demand was finally reached for all key components and materials in 2011 due to a slower than expected economic recovery in most industrialized countries. In fact, there is an overcapacity for many components and materials using standard processes.

In a buyer’s market, fierce competition for both quality and price has already pushed many suppliers, mainly from China, to the edge of collapse. Although established European suppliers are better positioned compared to newcomers in terms of perceptions of quality, reducing the product cost without sacrificing margins is still a challenge. Clearly, more consolidation will be seen in the supply chain in the next few years.

Apart from the key strategic parts, components and materials are being increasingly outsourced by large European turbine suppliers to Asia, particularly China which is the world’s largest wind power equipment manufacturing base. Although some European turbine OEMs are still hesitant to move away from their established suppliers, due to concerns over quality, economic pressure derived primarily from the decline in turbine prices is challenging turbine vendors, especially those who want to compete in the Chinese market, to accept higher risks to stay in the business.

Following the dramatic growth in installations, leading European turbine and key components suppliers had already shifted part of their manufacturing capacities to China and the U.S. the world’s two largest markets in terms of wind power installed capacity. However, manufacturers face important strategic decisions in diversifying their markets due to the uncertainty of developments in the US and the challenge of overcapacity in China. Suppliers are currently moving into new strategic markets such India, the UK and Brazil. Recently launched local content requirements in Brazil, Canada and India are also encouraging such a trend.

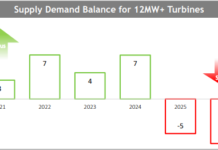

Overall, under current market conditions, many manufacturing facilities which had been geared to the fast growing wind market are running at part-load. There will therefore be enough capacity in the supply chain to cater for growth, assuming that the market follows BTM’s demand forecast for the next five years. The recent introduction of multi-MW offshore turbines (mostly 5-6 MW) by turbine manufacturers in both Europe and China, however, means that there may be a tight supply chain situation for some strategic components, partly because it takes time for the supply chain to prepare for mass production of such large parts.

Key Components

During the wind energy boom period, investors were increasingly favoring a vertically integrated approach to turbine manufacture.

More recently, however, the attitude towards investment has clearly changed from one of urgent enthusiasm to one of caution. With a buyers’ market, the pressure on the supply chain to meet market growth has gone, resulting in fierce competition for both product price and quality. In addition, the economic turmoil has significantly slowed down the availability of cash. Against this background, turbine manufacturers are much more willing to outsource components.

At the same time, with the average capacity of wind turbines steadily increasing, especially for the next generation of multi-MW offshore machines, the requirements from turbine manufacturers for both new technology and high quality components have limited the number of independent suppliers which can keep up with the pace of development. BTM indicates that these two factors have combined to create the current mainstream wind supply chain strategy.

Enercon is the only supplier in the Top 15 with full vertical integration in the manufacture of turbine components. Although the rest of the suppliers all have in-house capacity for producing vital components such as blades, gearboxes, generators and control systems, they still source a part of their supply from independent sub-suppliers. It is clear that blades and control systems are key components that most turbine OEMs prefer to produce in-house. With the secure supply of gearboxes becoming threatened, several large turbine vendors have adopted a strategy of buying out gearbox suppliers, but this situation has changed as supply chain bottlenecks have eased up with the recession.

Summary of Supply Status

This assessment indicates that although today the technical capacity for key materials exists on a global basis, there are a number of underlying issues which are a cause for concern.

The supply of castings and forgings, when considered on a global basis, suggests overcapacity. Both are, however, characterized by a strong regional imbalance in supply, with forgings in the US being in short supply and fears of tightness in Europe by 2014, despite a significant over capacity in China and South Korea. Severe overcapacity is complemented by fierce competition in both price and quality during a time where both higher raw material prices and labor costs plague European and North American suppliers. Partner selection still remains a

key challenge in meeting the strict quality specifications, an issue of growing concern as quality requirements increase with the trend towards increasing turbine size, a key concern for gearbox and bearing suppliers.

For the key materials used in the production of blades it is clear that there is no challenge in meeting demand with evidence for the necessary investment to ensure capacity is sufficient. Similarly, there are no concerns over the woven and stitched fabrics as close coordination between the suppliers and the market ensures that the necessary investment has been put in place to meet demand. The only concern remains in the pre-preg market where only a small subset of companies are providing pre-pregs. Despite recent investments, demand for pre-pregs is expected to be tight for the next few years until new suppliers enter this part of the value chain. Glass fiber is still expected to maintain its position as the material of choice for the general blade industry, although demand for an increase in the stiffness-to-weight ratio in blades catering to the offshore wind segment could mean that carbon fiber will increasingly come into favor. In terms of resins, there is a short-term tightness in the epoxy market due to the market supply of bisphenol A but there are no major long-term constraints expected for either epoxy or unsaturated polyester based solutions. It is still expected that epoxy resins will maintain the lion’s share of the market in all regions.

China is home to 97 percent of the world’s rare earth elements, a critical material in permanent magnet generators. With China gradually implementing export quotas, it has caused panic in the wind industry. Despite tightness expected for the next two or three years, there are positive movements from both the supply and demand side. Longer term, it is expected that a combination of new reserves, adaptive strategies from OEMs and governments as well as greater resource transparency will ensure that the industry has access to the resource.

There are no reports of any serious constraints in the supply chain for key components and materials at present, despite an increasing concern over the potential supply of rare earth materials. Based on the current supply chain situation that a lot of capacity will be available if European suppliers’ newly established facilities come into full operation, and a significant surplus of supply has been identified in China, there will be enough capacity in the supply chain to meet the modest annual growth rate of 15.5 percent up to 2015, the report’s authors state. Nonetheless, the recent trend for introducing multi-MW turbines (mostly 5-6 MW) by leading vendors indicates a sourcing challenge for large components and a challenge to get these industrialized quickly enough. This challenge can be eased, however, once the supply chain gains the confidence required to invest heavily.

More immediately, the report concludes, the wind energy boom has come to an end because of the ongoing global financial and economic crisis, with the previous tight situation in the supply chain easing in 2010. Due to the global economic recovery being slower than expected, and a slump in demand from the second quarter of 2011 onwards, not only has a balance been reached between supply and demand and but in most cases a significant surplus has been identified, prompting a flight to quality in a buyer’s market.

David Appleyard is Chief Editor of Renewable Energy World. He also currently holds the position of Chief Editor for sister publication Hydro Review Worldwide. A journalist and photographer, he graduated with a degree in Applied Environmental Science.